QWO Oxygen-Free Oven

Description:

- Effectively saves 30% of nitrogen consumption.

- With excellent airtightness, it can reduce the O2 to as low as 10 ppm.

- Special Pressure Relief Design.

Features

10ppm Oxygen-Free Key Technology- Special Pressure Relief Design: Utilizing an adjustable exhaust valve in conjunction with air intake control to maintain positive pressure inside the oven, ensuring a low-oxygen environment.

- Enhanced air tightness is achieved at the tubular heater cable outlet through a unique hermetic seal design.

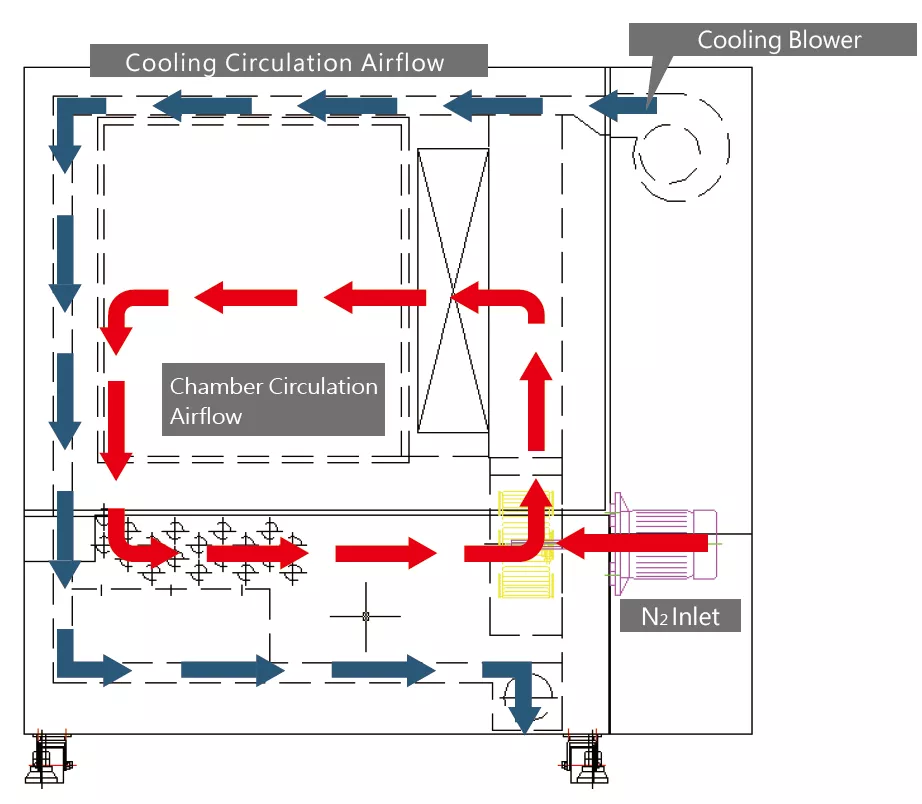

- N2 Throttling Design - Segregating the supply conduit into two - main and auxiliary – and with automated flow regulation.

- Cooling inter-layer design: a special indirect method to maintain an oxygen-free environment during cooling phase.

- Inner door design - establishing an invisible barrier of nitrogen gas that not only prevents external gases from entering but also inhibits heat dissipation.

- The inter-layer and the space between the inner and outer doors are filled with nitrogen (N2) to recover conducted waste heat for energy-saving.

Applications

IC packaging, wafer baking, film deposition and other industry manufacturing for drying productions. The equipment such as semiconductor drying equipment, circuit board drying equipment, PCB industrial oven, touch panel drying equipment, ABF carrier board drying equipment, precision industrial oven.

PC/PLC Controlled Oven Specification

↔️ Swipe right or left for more information

| Model | Internal Dimension WxDxH cm |

External Dimension WxDxH cm |

Power | Temperature Range | Temperature Uniformity |

| QHWO-2 | 61x61x61 | 145x113x122 | 220V 3φ 60HZ 9kvA/15kv |

+60~300℃ Max. +60~500℃ Max. |

300℃± 1.5%

500℃± 2%

|

| QWO-2DS (Dual Chamber Type) |

71x61x56 | 146x96x180 | 220V 3φ 60HZ 12kvA |

+60~250℃ Max. |

200℃± 1.5%

(Empty Furnace No-Load)

|

|

QWO-4D

(Walk-In/Truck-In Type)

|

71x61x91 | 138x90x140 |