Top-Down Airflow Auto Oven

Honored With the 32nd Taiwan Excellence Award

Merchandise number:ANWOL

Description:

- Exhaust recovery

- Parts early warning system

- Achieve the goal of factory automation

- Temperature precision control technology

- The intelligent throttling module

- Automatic door design

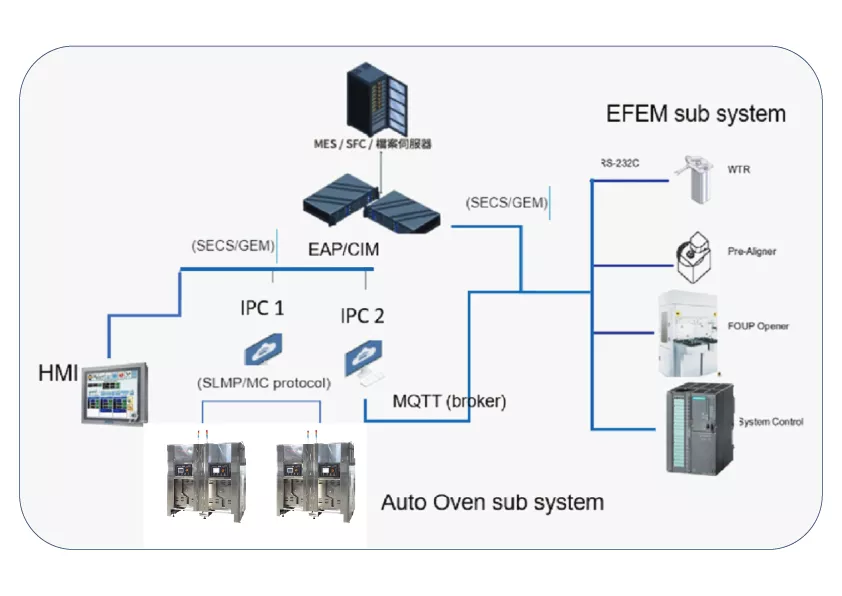

- Automation control and IoT integration

Features

Exhaust Recovery- The product features a patented multi-layer air door for 99% airtightness and improved thermal insulation design of the machine, resulting in a 20-25% boost in energy efficiency. With a new water-cooling system, it achieves an average cooling efficiency of 4.5°C/minute, enhancing UPH ( units per hour ) output. The machine uses recyclable materials with a 60% recycling rate. Incorporating waste heat and solvent recovery, it reclaims 25% of organic solvents, reducing adhesion of organic substances to the chamber and maintenance time, ensuring high product yield, and contributing to energy savings. This approach also minimizes environmental pollution and workplace accidents.

- In the application field of the drying process in PCB (Printed Circuit Board) manufacturing, there is a increasing emphasis on environmental safety in machine design. Therefore, the oven is equipped with features such as video surveillance and remote configuration systems. It includes smoke detectors, a touch screen, and an intuitive user interface to enhance machine operational efficiency while reducing incidents in workplace.

- The product is compatible with AGV/RGV/MGV or robotic arms. In addition to the existing communication protocol, it incorporates IPC, touchscreen displays, and independent applications, enabling a complete integration of the human-machine interface. Relevant machine data that it follows PCB ECI regulation can be uploaded to servers, and it can be combined with intelligent cameras to provide clients with connectivity to a smart factory.

- It allows real-time adjustments, ensuring temperature uniformity without the need for cooling.

- By leveraging the automatic adjustment feature of the intelligent throttling module, nitrogen quantity can be controlled, resulting in significant savings of nitrogen while maintaining the predetermined oxygen content within the furnace, achieving oxygen-free drying.

- The doors feature an automatic door design, with the capability for independent control of the two chambers.

- Built-in Sensors:To detect temperature, gas (O2 / N2) concentration, AGV battery capacity, positions of materials (Loader/Unloader/Ovens), and the status of automatic doors (open/close).

- Built-in motor drives:Installing automatic switching motors and controllers for the oven, AGV (drive motors and stacking), and air flow control motors, each equipped with a networked PLC controller in both loader and oven. The connectivity between the loader and robotic arms is established through Wi-Fi.

Applications

Industry automation in manufacturing for drying productions includes semiconductor, IC, PCB, Panel, ABF, LED, and electronics manufacturing. The equipment such as industrial dust-free drying oven, semiconductor drying equipment, circuit board drying equipment, PCB industrial oven, touch panel drying equipment, ABF carrier board drying equipment, N2 hot air oven.

PC/PLC Controlled Oven Specification

↔️Swipe right or left for more information

| Specification | |

| Process Temperature | RT ~450℃ |

| Temperature uniformity | ± 1.5% |

| Cleanliness | ISO14644-1 Class 5 @ 0.3 µm |

| Cooling Method | Air Cooling(N2/CDA)、Water Cooling |

| Compatible Equipment | EFEM 、Robotic arm |

| Oxygen Concentration | 20ppm |

| Operation Interface | User-Friendly operation interface, complies with .CIM .Ethernet & SECS/GEM .PCB ECI |

| Options | .Fast air-cooling system .Solvent recovery system .Quick-detachable inner liner |

| Process | .Curing for chips .Substrates in PR/PI processes Ideal for wafer-level and fan-out panel level packaging, providing the optimal curing solution. |